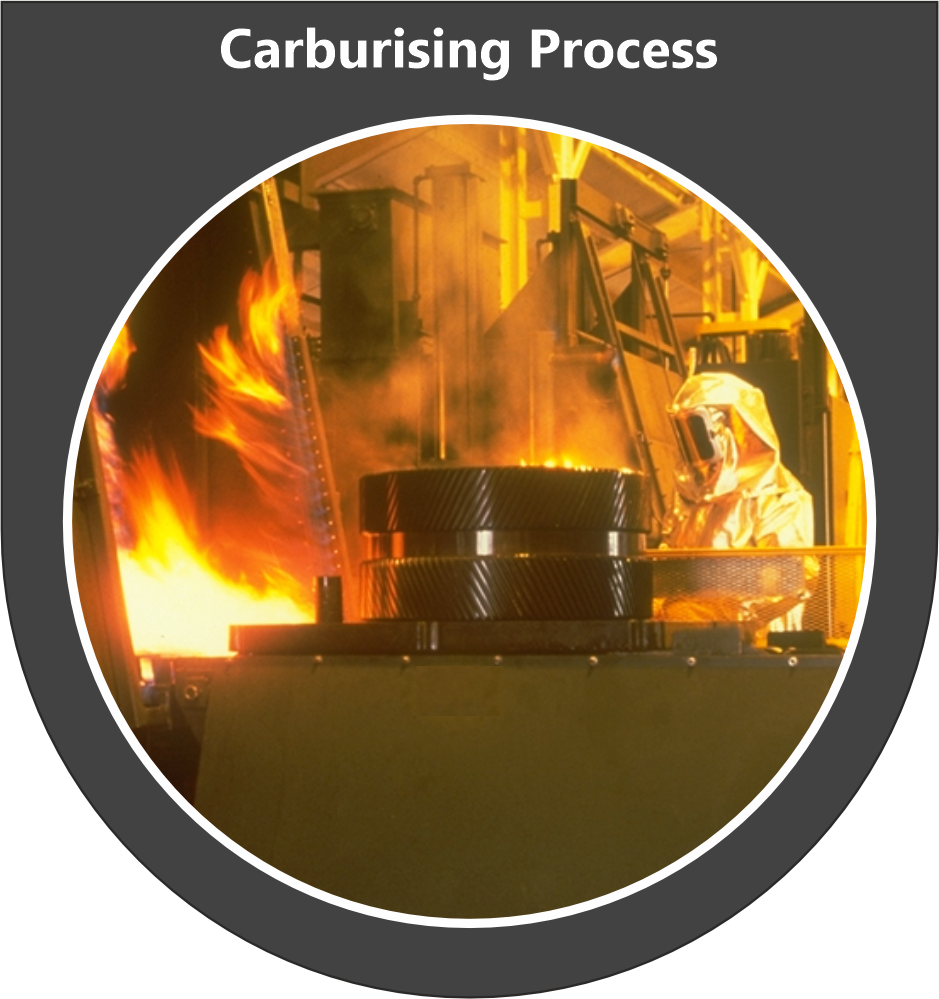

This is most commonly used surface hardening process for low carbon steels. Carburizing is a case hardening process that introduces carbon into a solid ferrous alloy. Metal is heated in carbon rich atmosphere above transformation temperature for pre decided time. After carburizing, parts are quenched to harden the surface carburizing layer.

Carbonitriding is process of simultaneously inducing both carbon & nitrogen into the surface of a component.. Carbonitriding is an ideal process for the hardening of small components, where great resistance to wear is required and generally operating where the case depth does not exceed 0.025” – 0.030”

Normalizing process is the heating of steel to a predetermined temperature for a while and then cooling it in air. This forms a microstructure with a mixture of ferrite and cementite with higher strength and hardness, but lower ductility. For improving the machinability of carbon steel, the structural components are heated to a suitable temperature and cooled in air.

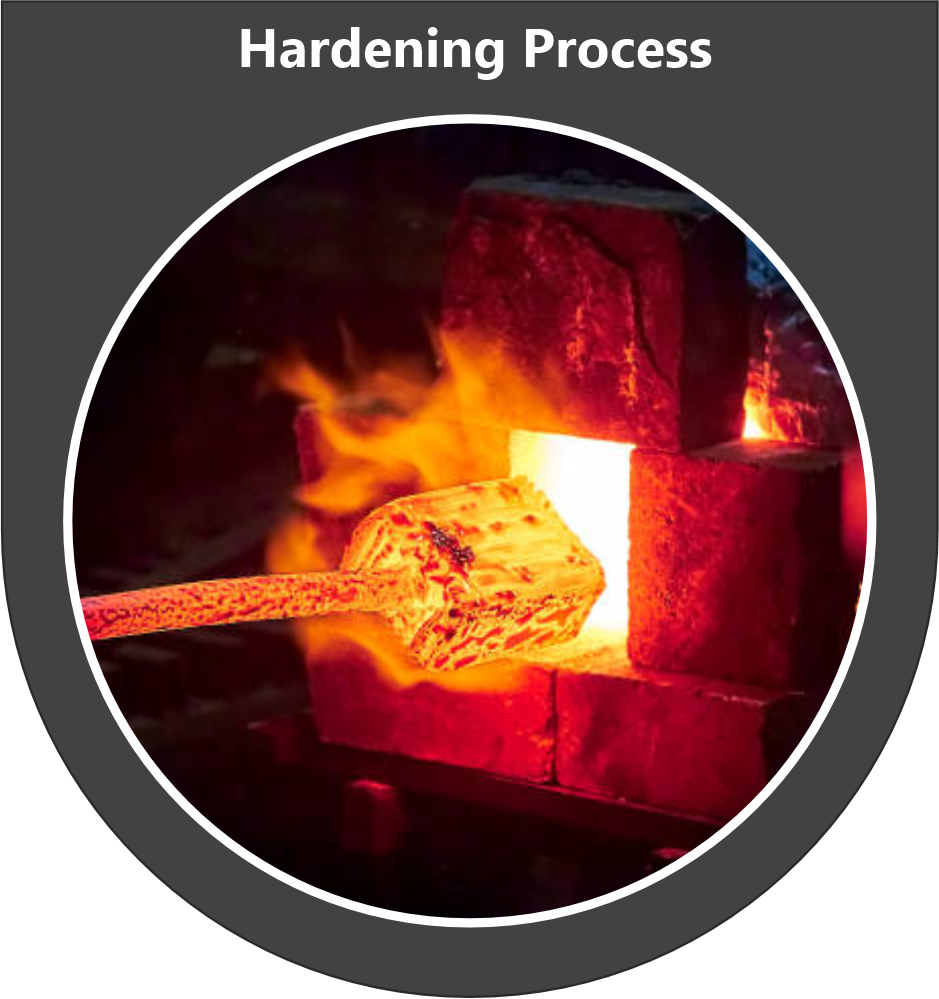

Case hardening process is done by hardening the outer layer of steel while maintaining a soft inner metal core. This is done for the carbon addition in the steel and the hardening depth depends on the application of case hardening. Case hardening is generally carried out for carbon steel forgings, steel pinions, machine parts for manufacturing etc.

Case hardening is carried out in producing horseshoes, cooking utensils and other bulk steel materials. This is carried out on the top surface and for a limited depth. Greater hardness gives better wear and fatigue resistance.

The case hardening is a process where the low carbon present in the metal combining with higher carbon contents. The grouping makes the metal much harder and thus by adding low carbon metal, it can be easily molded into desired shapes. This increases the product strength and assist in iron weakening.

Materials like firefighting equipment, cast iron, frying vessels require longer service time. Case hardening plays an important role in construction industry for reinforcing girders, metal panels and doors. This is performed after formation of component into its complete form.